Petroleum and natural gas

During the production process, the gas will carry a large amount of water vapor, condensate and solid impurities, and liquid will be generated with the change of temperature and pressure during the storage and transportation process. Liquid components and solid impurities will not only corrode pipelines, but also form solid hydrate plug valves, instrumentation equipment, and reduce pipeline transportation capacity.

Process flow chart of gas filtration and separation

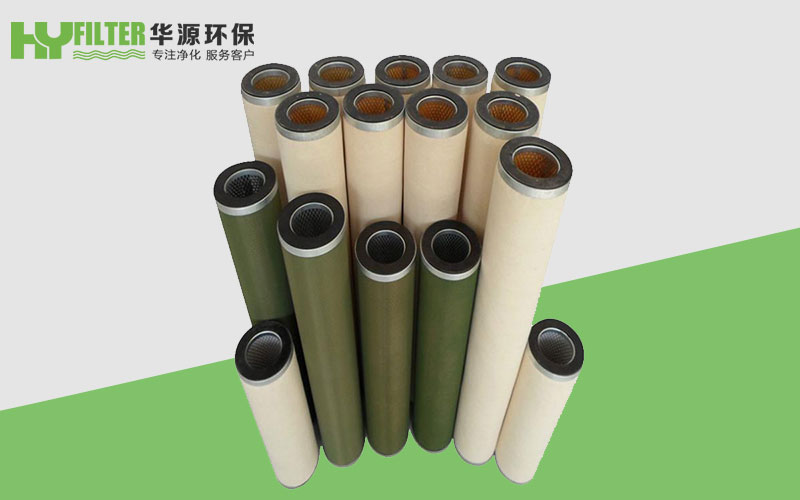

Gas Filter Separator

The gas filter separator adopts a conical aperture depth filter synthetic fiber filter element, which has high filtration precision and large dirt holding capacity. In the case of more pollution particles, it can be installed in front of the filter separator and used in series, which can effectively prolong the coalescence and filtration life of the filter separator. Installed before the use of flow meters and control valves, it can effectively intercept large-sized mechanical impurities and prevent their mechanical damage.

Main performance indicators

Initial pressure: 10KPa

Filtration precision: 0.3-200µm

Maximum allowable working pressure: 100KPa

Structural strength of filter: 700KPa

Filtration efficiency: ≥98%