Aviation

The quality and purity of aviation kerosene are highly demanded by aircraft. The impurities and water content of aviation kerosene will enter every step from refining to filling. Without effective pollution control, the flight safety will be seriously threatened.

Pre (micron) filters and filter separators can quickly and effectively remove tiny droplets and impurities in aviation kerosene without delay and any additional power to achieve high-efficiency and high-precision filtration.

Pre (micron) filters and filter separators have been widely used in aviation kerosene refining, storage, transportation, filling and other aspects from production to use, effectively protecting aircraft flight safety, using high technology and high Precision filter media based on fluid mechanics theory and deep filtration mechanism.

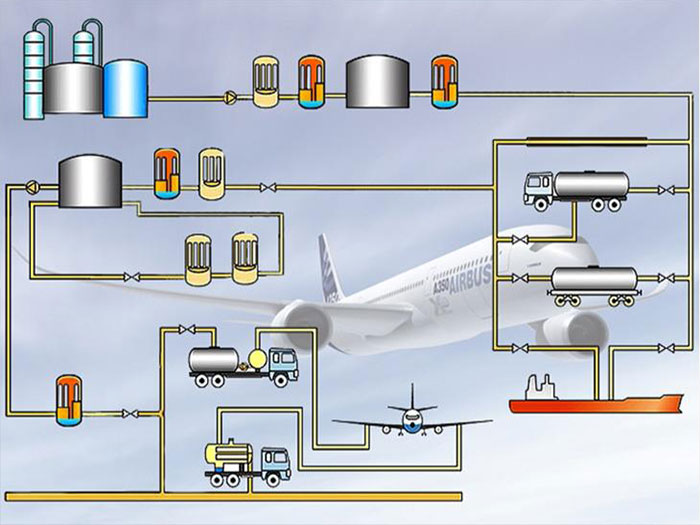

Schematic diagram of purification process for aviation

kerosene

Aviation kerosene products are mainly pre - (micron) filters and filter separators.

The main function of the pre (micron) filter is to remove particulate matter from the oil.

The main function of the filter separator is to remove tiny droplets in the oil.

Pre (micron) filters and filter separators are mainly used in airport aviation kerosene depots, terminals and oil pipelines. The safe use of aviation kerosene is achieved through the combination of the above filters.

Filter separator

The filter separator is the core unit of aviation kerosene purification. It has the dual functions of filtering impurities and removing water. It is filtered, coalesced and separated.

Remove the tiny droplets and impurities in oil products to meet the requirements of oil purification.

Main performance indicators:

1, initial pressure difference: < 30 KPa

2, sewage capacity: more than 1.43 g/ (L/min rated flow)

3. Cleanliness of filtered fuel:

A. free water content: < 15 ppm

B. solid impurity content: < 0.26 mg/L

C. fiber content: < 10 /L

4. Maximum allowable working pressure difference: 100 KPa

5. Structural strength of filter element: greater than or equal to 520 KPa

Pre (micron) filter

Pre (micron) filters are mainly used as protective filters for filter separators, flowmeters, control valves, etc. Finished products in refineries

In the case of serious particle pollution, such as storage, transit oil depot, Airport Oil depot, etc., it is installed in series in front of the filter separator and can be used.

It can effectively prolong the life of Coalescing filter element in filter separator, and effectively intercept when installed in front of flowmeter and control valve.

Large size mechanical impurities prevent mechanical damage.

Main performance indicators:

1, initial pressure difference: < 20 KPa

2, sewage capacity: more than 3 g/ (L/min rated flow)

3. Maximum allowable working pressure difference: 100 KPa

4, filtering accuracy: 1, 3, 5, 10, 15, 20... M

5. Structural strength of filter element: greater than or equal to 520 KPa