Production process of hydraulic oil filter element-HUAYUAN FILTER

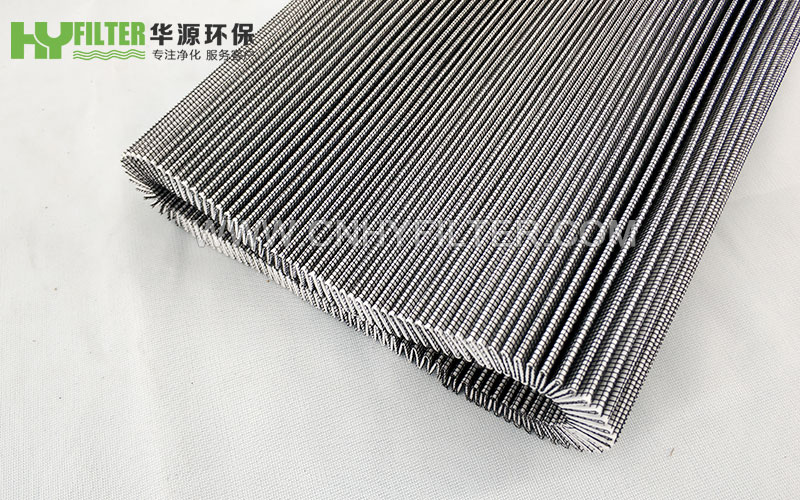

First of all, the choice of filter material and filter element is the key to determining the filter effect of the filter element. Generally, the filter material of the Hydraulic oil filter element is glass fiber, because the filter element made of glass fiber can not only retain the impurities in the hydraulic oil, but also be sharp, break the oil bag, and fully filter. As for the selection of filtration precision, it is necessary to meet the hydraulic requirements in the hydraulic environment. Xinxiang Huayuan Environmental Protection Technology Co., Ltd. has decades of experience in the production and development of hydraulic oil filter elements.

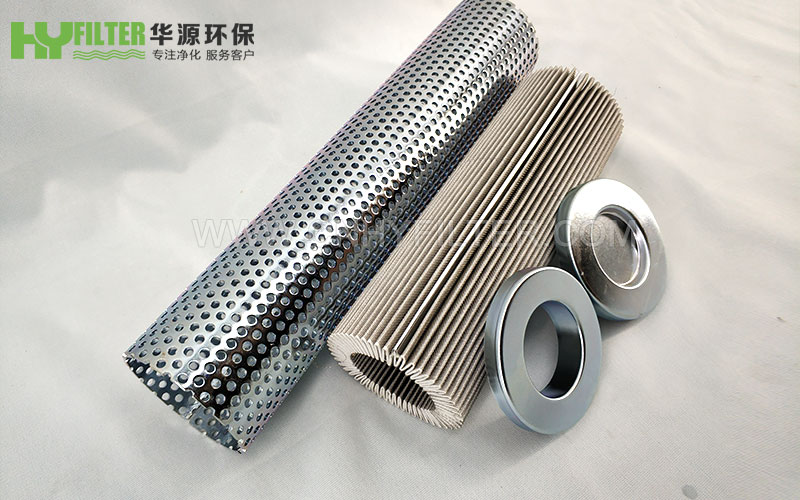

Then, we select the end caps. When we choose end caps for filter elements, we usually choose stamped parts, that is, 0.8mm galvanized end caps or machined aluminum end caps. However, some filter elements have bypass valves, so plastic end caps with bypass valves are selected at this time. At the same time, a variety of considerations are combined to determine the choice of end cover material, because the working pressure that can be endured is also different because of the different positions used.

Select support tube. Generally in ordinary hydraulic oil, our support tube is made of Q235 carbon steel punching piece. The thickness of the filter support tube is mainly determined by the pressure to which the filter is subjected. Choose a thickness of 0.8mm, but sometimes blindly pursue price. In order to retain customers, some manufacturers will choose a thickness of 0.5mm or even 0.3mm, so that the appearance of the filter will not change, but the normal pressure capacity of the filter will be greatly reduced. Of course, according to different filter media, the support tube can also be made of stainless steel, aluminum, plastic and other materials.

After the material of the filter element support tube is selected, the filter element is processed. The filter process is simple and responsible. The first step is to cut the media to size, set up the support tubes, and match the end caps. The second step is to fold, trim and stitch the filter media with mechanical equipment. The filter material and support tube are secured together with the end cap. There is also a very important material in the middle, epoxy glue, which is used to fix the end cap and sew the filter material.

Such a complete filter element is completed. Although the process of the filter element is simple and there are many kinds of filter materials, the user should consider the price when choosing the filter element, but the quality of the filter element is the key.